3D printing isn’t just for prototypes anymore, though the ability to rapidly prototype IS pretty cool. If you’ve ever wondered why we chose to 3D print instead of inject mould like everyone told us we had to, this should answer your questions.

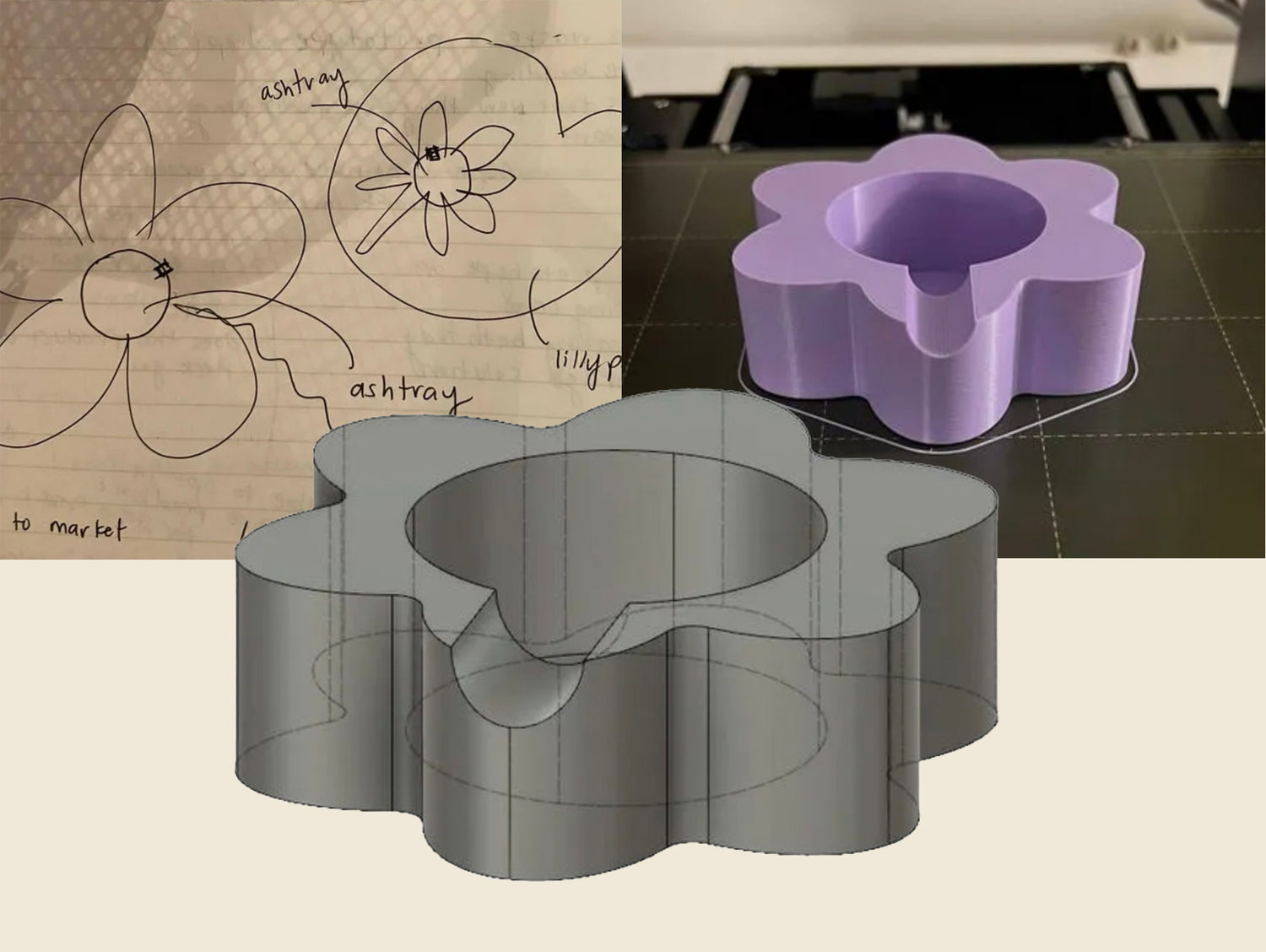

🌼 The Floating Ashtray 🌼 is a great example of why 3D printing KICKS ASS — you can read The Making Of The Floating Ashtray on the Sticky Bits Substack here.

Photo Caption: Shafeez working away on The Floating Ashtray, and staring at the beginning layers of the Lily Pad. Only about 4.2 hours to go.

1. 3D printing gives us the flexibility to continue iterating on our design

When developing a new product at Another Room, we’re able to prototype, iterate, and finalize a design all within the world of 3D printing. It’s a major benefit that injection moulding does not offer. This means we spend way more time focusing on the smallest details, and have the flexibility to iterate and update the product design whenever we need or want to. With injection moulding, this is simply not possible. If you want to change even one aspect of that design, you have to create a new mould, and it requires a sizeable investment of money and time – leaving little room for smaller, self-funded teams.

The fact that we can turn a doodle into a physical object within the span of a week is pretty fucking amazing, if we do say so ourselves. And we do.

Photo Caption: The process of seeing The Floating Ashtray go all the way from sketch, to rendering, all the way to 3D printed product.

2. Being able to 3D print at home and at scale!

When we're working on something in the home studio, it can all happen within a few days. Once our doodle goes from rendering, to printing a physical object, we can assess and determine how we want to refine it. With just a few simple updates to a digital file, we can save a new version of the product, and 3D print it again. This process allows for quick and easy iterations. And it's super easy for Shafeez to show Chloe what things look like over FaceTime!

Photo Caption: Shafeez showing Chloe how these 3 basic rolling trays look in Internet Blue, Kelly Green, and Safety Orange.

Video Caption: Shafeez printing off a Strawberry Red Joint Cone on a Prusa Mini 3D Printer in his home studio.

When working with our 3D print farms in the USA, we focus on refining product features to streamline the production process—from reducing rejection rates to improving design scalability. What's more, prototyping can happen remotely. Shafeez, in his Toronto home studio, collaborates with the 3D print farms. They update designs, send us files, and we print prototypes in Shafeez's studio to gather detailed feedback. This remote process allows for quick iterations and improvements.

Video Caption: Makelab printing the latest set of Floating Ashtrays for Another Room.

3. Maintaining a lower waste manufacturing process

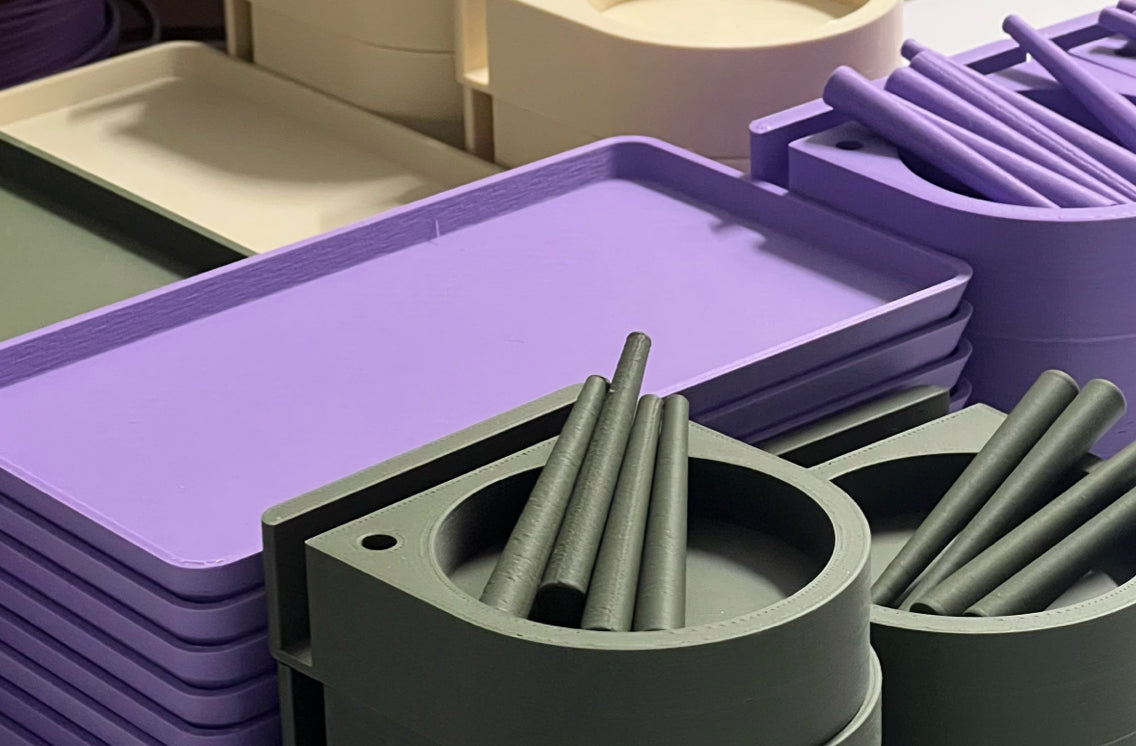

We recognize that we make consumer goods, which inherently means more things exist in the world. Given this reality, we aim to create only what's needed, as much as possible. If we need 20 units, we print 20 units. And if we’re doing larger print runs, it doesn’t have to be more than 1000 units. It can be, but it doesn’t HAVE to be in order to keep our products accessibly priced. This keeps us from overstocking and prevents the headaches of managing excess inventory, allowing us to focus on quality and demand rather than scrambling to offload surplus.

Photo Caption: Products from the prototype shop hanging out together.

4. The ability to make …literally anything

We LOVE making stuff; the process of it, the challenges, getting to see ideas that lived rent-free in our minds become physical objects in our hands. And making stuff with other brands and people makes the process even better. 3D printing opens up an entirely untapped world of being able to create, invent, and produce products — both at scale, and in small batches. The endless possibilities of 3D printing are both exciting and overwhelming.

Dive into our world of 3d printing

Curious about plant–based plastic? Keen to know why we’re 3D printing instead of injection moulding? Unsure what a grip fin is? Have no idea what any of that means?